CO₂ Incubator Repair Service|Gas Intake Failure & Panel Malfunction

CO₂ Incubator Repair

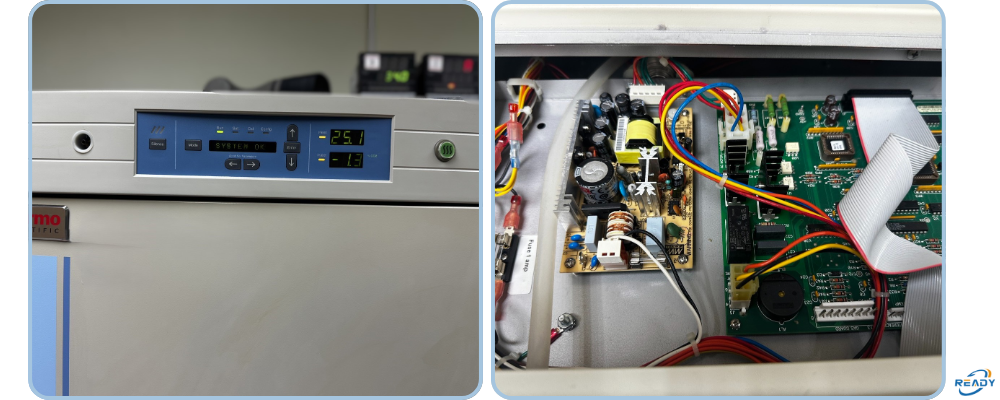

After long-term use, CO₂ incubators may experience issues such as gas intake failure, flashing control panels, or abnormal alarms. These problems are commonly related to aging gas pathway components, solenoid valve malfunction, sensor drift, or control module failure. If not addressed promptly, unstable CO₂ concentration and temperature control may negatively impact cell culture quality and experimental reproducibility.

READY provides comprehensive troubleshooting and repair services for CO₂ incubators. Based on the actual condition of the equipment, necessary components such as gas intake parts, control panel modules, or sensor-related parts are replaced. After repair, the incubator is verified to ensure normal gas intake, stable display performance, and proper operational functionality.

Because displayed values on CO₂ incubators may differ from actual measured values—especially after repair or component replacement—temperature and CO₂ concentration verification and calibration are strongly recommended. By comparing readings with calibrated reference instruments, the actual operating condition of the incubator can be confirmed, reducing the risk of inaccurate culture environments.

READY offers an integrated one-stop service covering CO₂ incubator repair, verification, and calibration. This service supports biotechnology companies, cell culture laboratories, pharmaceutical QC/QA departments, and academic institutions in restoring reliable equipment performance and maintaining stable culture conditions.

Experiencing gas intake failure or control panel malfunction with your CO₂ incubator? Contact READY for professional repair, component replacement, and post-repair verification and calibration services.

☎︎ Tel: 02-8228-0131

✉️ Email: Ready_lab@outlook.com