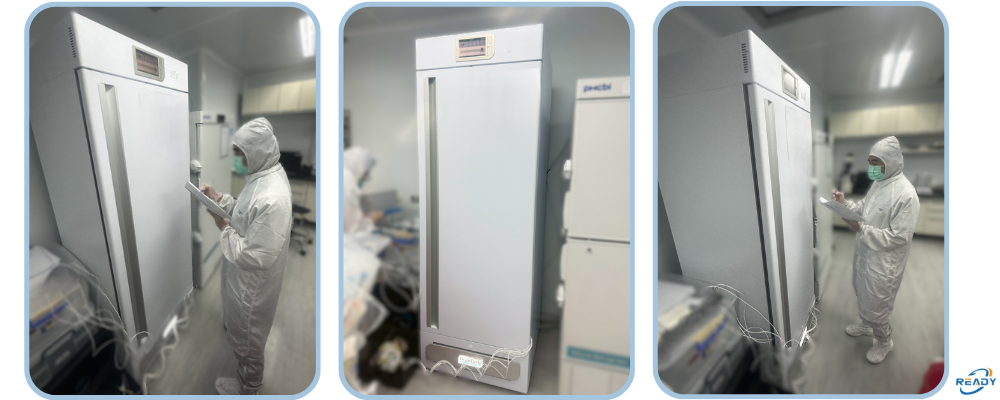

4°C Refrigerator Validation|6-Point Temperature Mapping (12 hrs)

Why 4°C Refrigerator Validation Is Essential

In biotechnology labs, QC units, pharmaceutical storage, and sample preservation workflows, 4°C refrigerator validation ensures temperature accuracy, sample integrity, and compliance with QA/SOP requirements.

Functional Inspection (Per Customer Requirement)

READY performs a complete functional check before temperature mapping:

• Exterior condition

• Door function check

• Gasket sealing condition

• Control panel button inspection

• Display accuracy check

• Operation & noise evaluation

This step helps identify early issues such as temperature fluctuation, air leakage, or mechanical wear.

6-Point Temperature Mapping (12 Hours)

Once the temperature stabilizes, we begin 6-point mapping:

• Continuous 12-hour temperature recording

• Raw data provided

• Temperature curve graph included

• Validation result based on customer acceptance criteria

This evaluates Uniformity and Stability of the refrigerator.

Uniformity & Stability Evaluation

We analyze maximum point-to-point variation and verify continuous temperature stability throughout the recording period.

Validation Result & Recommendations

If deviations occur, our report provides:

• Nonconformity findings

• Possible causes

• Suggested corrective actions

Who Needs READY’s Refrigerator Calibration Service

✔ Biotechnology laboratories

✔ Hospitals & clinical labs

✔ Pharmaceutical QA/QC units

✔ Food and chemical testing facilities

✔ Any research unit requiring stable 4°C storage

☎︎ Tel: 02-8228-0131

✉️ Email: Ready_lab@outlook.com