Replacement filter for CO2 incubator | Improve culture quality and avoid equipment abnormalities

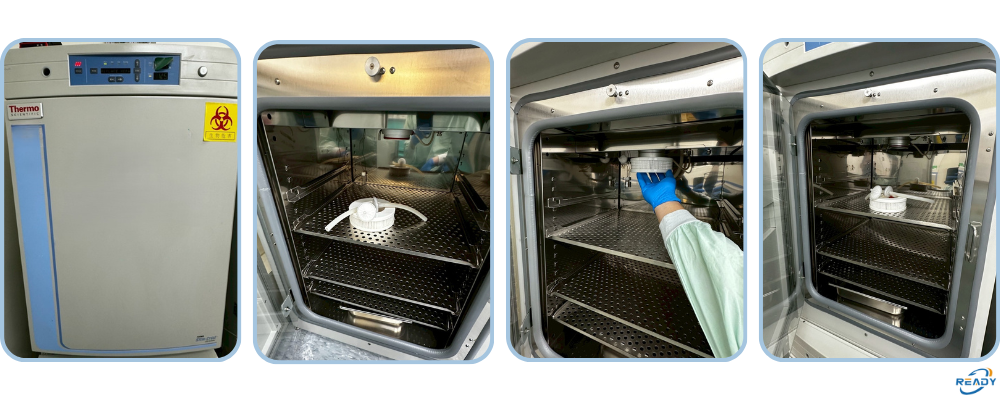

CO₂ Incubator Filter Replacement & Gas Line Maintenance Services

Ensure Stable Cell Culture Conditions with Regular HEPA Filter Replacement

Over time, CO₂ incubators accumulate airborne particles, moisture, and impurities inside their gas filters (such as HEPA or internal filters). This buildup can lead to unstable gas flow, inaccurate CO₂ concentration, and compromised culture conditions.

Without regular filter replacement, the incubator may experience CO₂ pressure fluctuations, decreased humidity, or even trigger system alarms and shutdowns.

To maintain optimal equipment performance and ensure experimental accuracy, it is recommended to replace filters every 6 to 12 months, depending on usage frequency, and perform pressure calibration and gas line maintenance simultaneously.

✓ READY Biotech Offers the Following Services:

▪️ CO₂ Incubator Filter Replacement

HEPA or internal filter replacement based on model specifications and usage conditions.

▪️ Gas Flow & Pressure Abnormality Diagnostics

Check for unstable CO₂ delivery or airflow inconsistencies.

▪️ CO₂ Supply System Calibration & Maintenance

Adjust gas pressure and ensure proper flow rate for optimal culture performance.

▪️ Full Equipment Inspection & Maintenance Recommendations

Evaluate overall performance and provide tailored upkeep suggestions.

READY Biotech’s professional technical team has extensive experience serving biotech firms, hospitals, pharmaceutical manufacturers, and academic research institutions.

We provide on-site assessment and calibration to ensure your laboratory equipment remains safe, stable, and compliant with quality standards.

Schedule Your CO₂ Incubator Filter Replacement Today!

Let our experts help you maintain a clean, stable, and CO₂-regulated environment for your critical applications.

☎︎ Contact Us:+886-2-8228-0131

✉︎ Email: Ready_lab@outlook.com